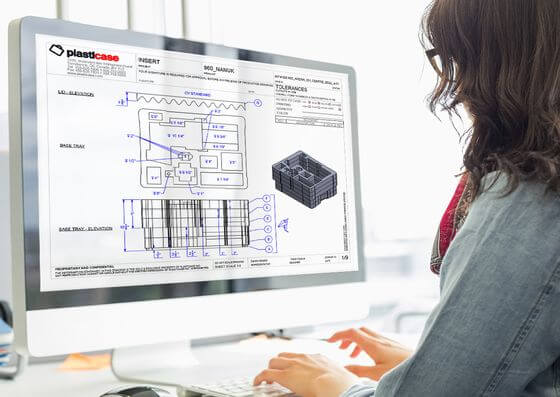

1. Select your case

Case selection is the first step in the custom foam design process. Depending on your project requirements, you may need a case that’s tough and waterproof with a lifetime warranty—NANUK is the case you need. Looking for something stylish and affordable? Our Designer series may be the way to go. Once the case is chosen, the final step in the selection process is to decide on a color.